Download DP Technology ESPRIT 2020 R1 free latest version offline setup for Windows 32-bit and 64-bit. DP Technology ESPRIT 2020 R1 is a powerful application for different CAD/CAM operations with realistic simulation features.

DP Technology ESPRIT 2020 R1 Overview

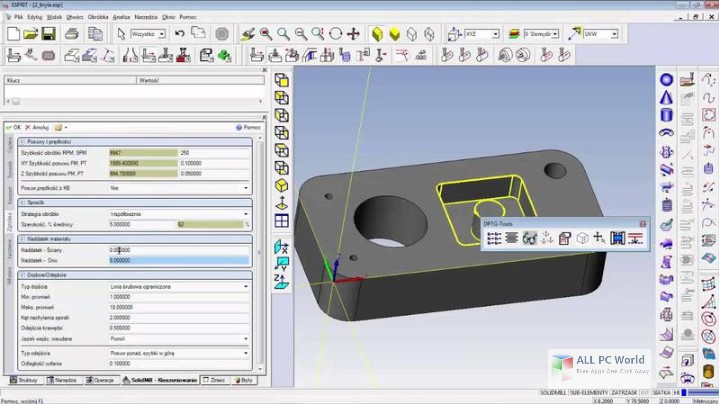

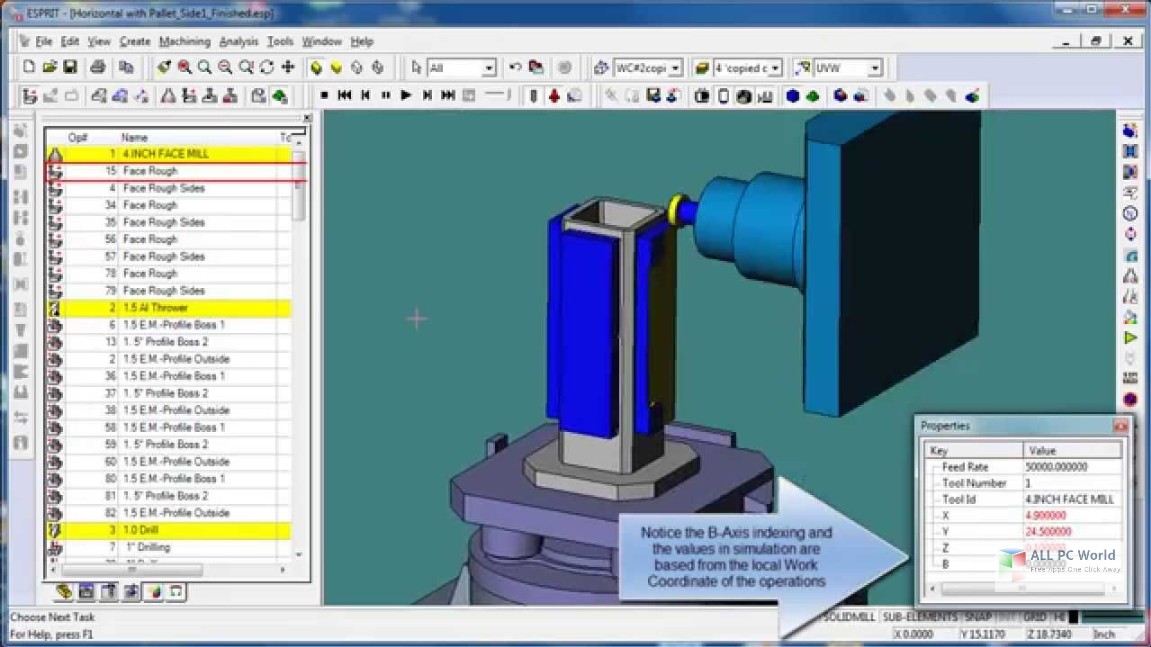

DP Technology ESPRIT is a leading computer-aided manufacturing (CAM) software solution designed to streamline and optimize the machining process. With a robust set of features, ESPRIT is renowned for its ability to generate efficient and accurate toolpaths for complex machining operations. The software supports a wide range of CNC (computer numerical control) machines, including milling, turning, and wire EDM (electrical discharge machining) systems. One of its key strengths lies in its intelligent machining algorithms, which allow users to achieve high precision and productivity in their machining tasks. ESPRIT’s user interface is user-friendly and intuitive, providing an extensive array of tools for CAD/CAM integration. This enables seamless transition from design to manufacturing, ensuring that the final product matches the intended design specifications. The software supports various CAD formats, enhancing its compatibility with different design systems. Its simulation capabilities are noteworthy, allowing users to visualize and validate machining processes before actual production, minimizing errors and optimizing toolpath strategies.

The software’s multi-axis machining capabilities are a highlight, enabling users to program complex parts with intricate geometries. ESPRIT’s advanced algorithms optimize toolpaths for multi-axis machines, enhancing efficiency and minimizing tool wear. Additionally, the software offers a comprehensive set of features for machining different materials, accommodating the diverse needs of industries ranging from aerospace to medical. In terms of automation and optimization, ESPRIT excels with its ability to generate toolpaths automatically based on defined parameters. This not only saves time but also ensures consistency and accuracy in machining operations. The software’s integration with Industry 4.0 principles allows for connectivity and data exchange, facilitating a smarter and more interconnected manufacturing environment. Furthermore, ESPRIT provides extensive post-processing options, allowing users to customize and fine-tune their NC (numerical control) programs to match the requirements of specific machines. This flexibility is crucial in adapting to the varied specifications of different CNC machines available in the market.

In summary, DP Technology ESPRIT stands out as a comprehensive and versatile CAM solution, leveraging advanced algorithms, user-friendly interfaces, and powerful simulation capabilities to enhance the efficiency and precision of machining processes across various industries. Its commitment to automation, multi-axis machining, and integration with Industry 4.0 principles positions ESPRIT as a key player in the realm of computer-aided manufacturing.

Features

- Multi-Axis Machining: ESPRIT excels in providing advanced multi-axis machining capabilities, allowing users to program complex parts with intricate geometries efficiently.

- CAD/CAM Integration: The software seamlessly integrates with various CAD systems, facilitating a smooth transition from design to manufacturing.

- Intelligent Machining Algorithms: ESPRIT employs intelligent algorithms to generate efficient and accurate toolpaths, optimizing machining processes for high precision and productivity.

- Simulation Capabilities: Users can visualize and validate machining processes through comprehensive simulation features, minimizing errors and optimizing toolpath strategies before actual production.

- CNC Machine Compatibility: ESPRIT supports a wide range of CNC machines, including milling, turning, and wire EDM systems, enhancing its versatility for different manufacturing needs.

- User-Friendly Interface: The software boasts a user-friendly and intuitive interface, ensuring ease of use for both novice and experienced users.

- CAD Format Support: ESPRIT supports various CAD formats, enhancing its compatibility with different design systems and improving the interoperability of data.

- Industry 4.0 Integration: ESPRIT embraces Industry 4.0 principles, allowing for connectivity and data exchange to create a smarter and more interconnected manufacturing environment.

- Automation Capabilities: The software offers automation features, allowing users to generate toolpaths automatically based on defined parameters, saving time and ensuring consistency.

- Optimization Tools: ESPRIT provides optimization tools to fine-tune toolpaths, enhancing efficiency and minimizing tool wear in machining operations.

- Post-Processing Options: Extensive post-processing features enable users to customize and refine NC programs to match the specific requirements of different CNC machines.

- Material Library: ESPRIT includes a comprehensive material library, accommodating the diverse needs of industries by providing specific parameters for machining different materials.

- Toolpath Editing: Users can easily edit and modify toolpaths to meet specific design and manufacturing requirements.

- High-Speed Machining (HSM): The software supports high-speed machining techniques, optimizing toolpaths for increased efficiency in cutting operations.

- Thread Milling Support: ESPRIT offers specialized features for thread milling, allowing for the efficient machining of threaded components.

- Electrode Machining: For EDM applications, ESPRIT provides advanced features for electrode machining, ensuring precision and accuracy in the manufacturing of intricate shapes.

- Turn-Mill Capabilities: The software supports turn-mill operations, enabling users to program and optimize machining processes for both turning and milling on multi-tasking machines.

- Collision Detection: ESPRIT includes collision detection features to identify and prevent potential collisions between the tool and the workpiece during machining.

- Tool Library Management: Users can efficiently manage tool libraries, ensuring the availability of the right tools for specific machining tasks.

- Adaptive Machining: ESPRIT incorporates adaptive machining strategies, dynamically adjusting toolpaths based on changing conditions to optimize performance.

- Machine Simulation: Detailed machine simulation features provide a virtual representation of the machining process, helping users visualize and analyze operations.

- Tolerance-Based Machining: The software supports tolerance-based machining, allowing users to define machining strategies based on specified tolerances for enhanced precision.

- Customizable Templates: Users can create and customize machining templates, streamlining the programming process for repetitive tasks.

- Toolpath Optimization for Additive Manufacturing: ESPRIT extends its capabilities to support toolpath optimization for additive manufacturing processes, ensuring efficiency and accuracy.

- Integrated G-code Editing: Users can perform G-code editing directly within the software, streamlining the process of refining and adjusting machining programs.

- In-Process Stock Monitoring: ESPRIT includes features for in-process stock monitoring, enabling users to track material removal during machining operations.

- Toolpath Verification: Comprehensive toolpath verification tools help users validate and ensure the accuracy of programmed toolpaths.

- Machining Strategy Planning: The software assists users in planning machining strategies, optimizing toolpaths for specific manufacturing requirements.

- CAM for Swiss-Type Machines: ESPRIT supports Swiss-type machines, providing specialized CAM features for the efficient programming of these precision machining systems.

- User Training and Support: DP Technology offers training and support resources to help users make the most of ESPRIT’s features, ensuring a smooth and productive experience.

Technical Details

- Software Name: DP Technology ESPRIT For Windows

- Software File Name: DP-TECHNOLOGY-ESPRIT-2020-R1.rar

- Software Version: 2020 R1

- File Size: 1.55 GB

- Developer: DP Technology

- File Password: 123

- Language: Multilingual

- Working Mode: Offline (You don’t need an internet connection to use it after installing)

System Requirements for DP Technology ESPRIT

- Operating System: Windows 11/10/8/7

- Free Hard Disk Space: 2 GB of minimum free HDD

- Installed Memory: 1 GB of minimum RAM

- Processor: Intel Core 2 Duo or higher

Download DP Technology ESPRIT Latest Version Free

Click on the below link to download the latest offline setup of DP Technology ESPRIT for Windows x86 and x64 architecture. You can also download Mastercam 2019 v21.0

File Password: 123