Download Geometric NestingWorks 2023 SP4 for SolidWorks 2018-2020 free latest version offline setup for Windows 64-bit. Geometric NestingWorks 2020 SP1 is a useful plugin for SolidWorks 2018-2020 providing a variety of powerful tools for modeling in different layers and components so as to conveniently work on complex models.

Geometric NestingWorks 2023 SP4 Overview

Geometric NestingWorks stands out as a powerful and specialized software designed to optimize the nesting process for sheet metal and fabrication on the Windows platform. As an essential tool for engineers, manufacturers, and designers, this parametric nesting software offers a range of features aimed at maximizing material utilization and minimizing waste in the manufacturing process.

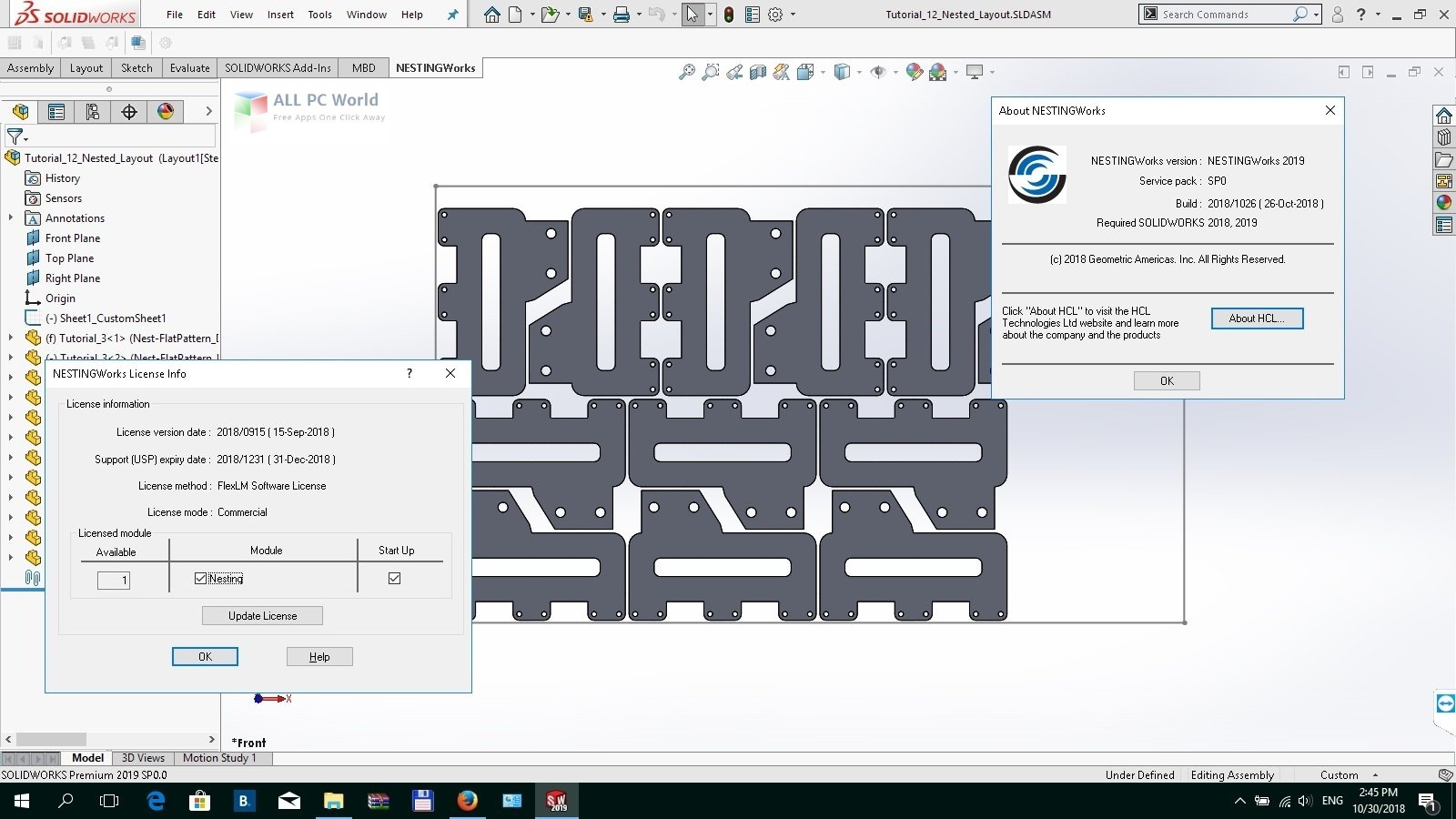

The software’s core functionality revolves around its parametric nesting capabilities, allowing users to automatically arrange and optimize parts on a sheet. This advanced feature ensures that manufacturers can achieve the highest level of efficiency in material usage, leading to cost savings and improved overall productivity.

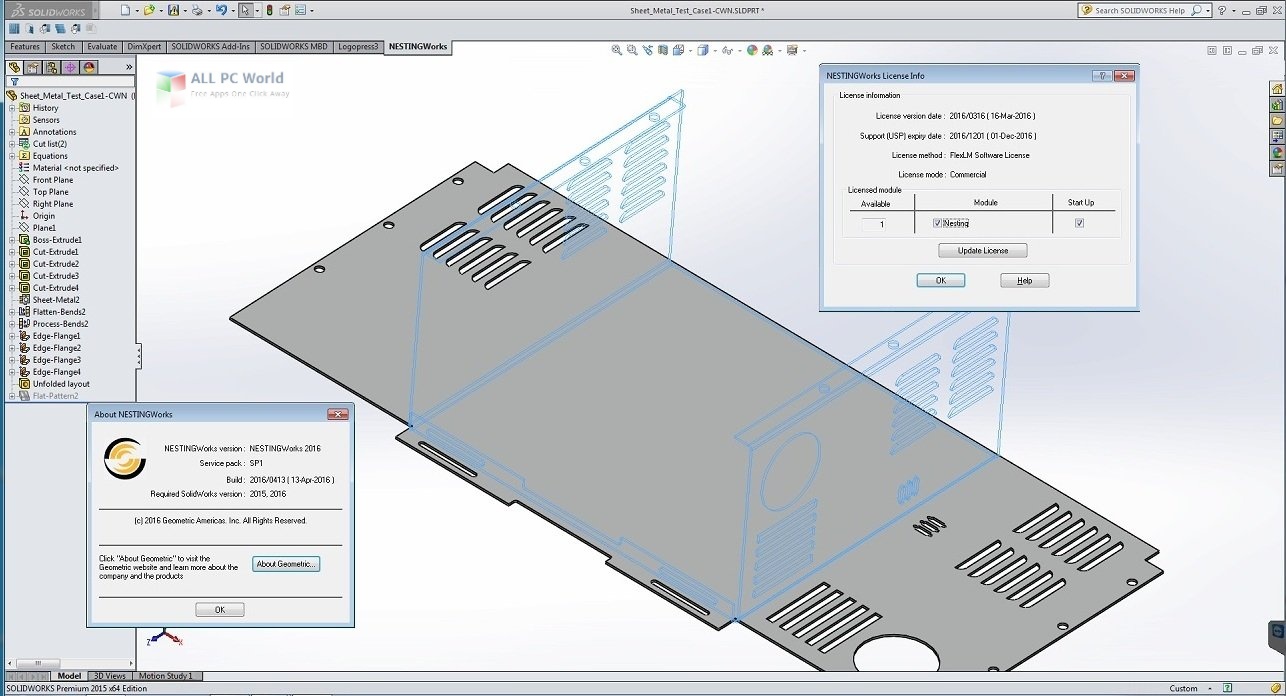

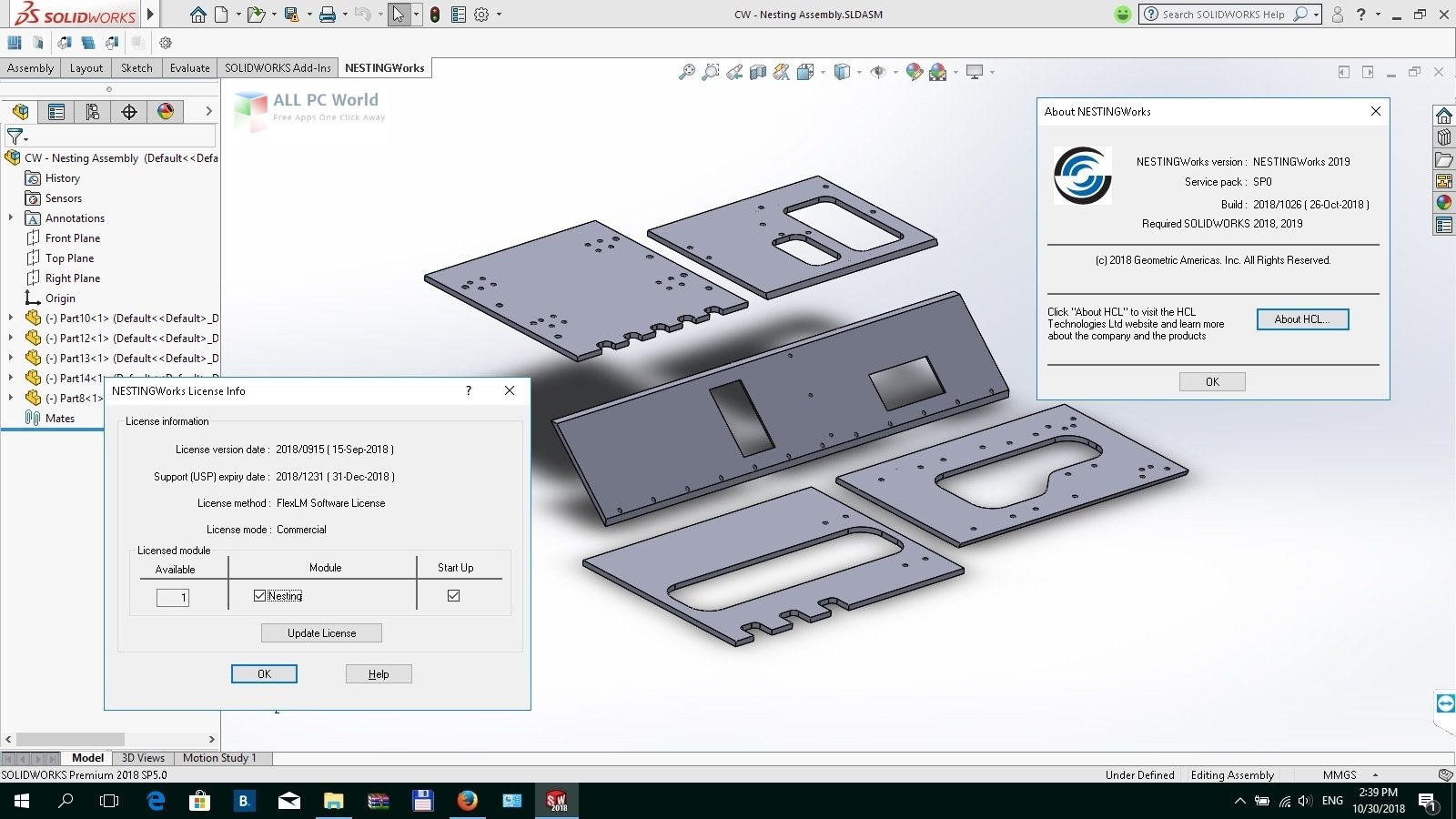

A distinctive aspect of Geometric NestingWorks is its seamless integration with SolidWorks, a widely used 3D CAD software. This integration enhances the overall design-to-manufacturing workflow, allowing users to create and modify 3D models in SolidWorks and seamlessly transfer them to NestingWorks for optimization without the need for data translation or additional steps.

The software’s user-friendly interface adds to its appeal, providing engineers and designers with intuitive controls and a clear layout for efficient navigation. The straightforward design ensures that users can quickly adapt to the software, minimizing the learning curve and enabling faster implementation in the manufacturing process.

In addition to its parametric nesting capabilities, Geometric NestingWorks introduces advanced algorithms for collision detection and part orientation. These algorithms contribute to the optimization process by ensuring that parts are arranged on sheets with precision, avoiding collisions and optimizing the cutting path for manufacturing equipment.

Understanding the importance of customization in manufacturing processes, the software offers configurable nesting strategies. This allows users to tailor the nesting process to specific manufacturing requirements, accommodating different materials, sheet sizes, and production constraints with ease.

For users in the sheet metal and fabrication industry, Geometric NestingWorks introduces automated updates. This feature ensures that nesting configurations and layouts automatically update when design changes are made in the associated SolidWorks models, maintaining synchronization between the design and manufacturing stages.

Furthermore, the software supports report generation, providing users with detailed reports on material utilization, efficiency gains, and nesting statistics. These reports offer valuable insights for manufacturers, enabling them to analyze and optimize their processes further.

In conclusion, Geometric NestingWorks emerges as an indispensable tool for manufacturers looking to streamline their sheet metal and fabrication processes. With its parametric nesting capabilities, seamless SolidWorks integration, user-friendly interface, advanced algorithms, configurable nesting strategies, automated updates, and report generation features, it stands as a go-to solution for achieving optimal material utilization and efficiency gains in the manufacturing workflow.

Features

- Parametric Nesting: The software excels in parametric nesting, automatically arranging and optimizing parts on a sheet for optimal material utilization.

- Integration with SolidWorks: Seamless integration with SolidWorks, allowing users to create and modify 3D models seamlessly for a streamlined design-to-manufacturing workflow.

- User-Friendly Interface: A user-friendly interface with intuitive controls ensures efficient navigation, minimizing the learning curve for engineers and designers.

- Advanced Algorithms: The software incorporates advanced algorithms for collision detection and part orientation, contributing to precise and optimized part placement.

- Configurable Nesting Strategies: Offers configurable nesting strategies, allowing users to customize the nesting process to meet specific manufacturing requirements.

- Automated Updates: Supports automated updates, ensuring that nesting configurations automatically adjust when design changes are made in associated SolidWorks models.

- Sheet Metal Optimization: Specialized for the sheet metal and fabrication industry, providing tailored solutions for efficient material utilization.

- Efficient Design-to-Manufacturing Workflow: The SolidWorks integration enhances the design-to-manufacturing workflow, eliminating the need for data translation or additional steps.

- Collision Detection: Advanced algorithms include collision detection, ensuring that parts are arranged on sheets with precision to avoid interference.

- Part Orientation Optimization: Optimizes part orientation on sheets, contributing to a more efficient cutting path for manufacturing equipment.

- Customization Capabilities: Users benefit from customization capabilities, adapting the software to accommodate different materials, sheet sizes, and production constraints.

- Automated Material Utilization Reports: The software generates detailed reports on material utilization, providing valuable insights for analysis and process optimization.

- Efficiency Gains: Offers insights into efficiency gains through detailed reports, allowing manufacturers to continually improve their processes.

- Synchronization with SolidWorks Models: Ensures synchronization with SolidWorks models, maintaining consistency between design changes and the manufacturing stage.

- Streamlined Design Changes: Automated updates streamline the process of implementing design changes into the nesting configurations.

- Precision in Part Placement: The advanced algorithms contribute to the precision in part placement, optimizing the sheet for minimal waste.

- Seamless Material Utilization: Parametric nesting ensures seamless material utilization, reducing waste and cutting costs in the manufacturing process.

- Tailored Manufacturing Solutions: Configurable nesting strategies offer tailored solutions for specific manufacturing needs, enhancing flexibility.

- Enhanced Productivity: The software significantly enhances productivity by automating complex nesting processes and providing efficient tools.

- Optimized Cutting Path: Advanced algorithms optimize the cutting path, contributing to increased efficiency in manufacturing equipment operation.

Technical Details

- Software Name: Geometric NestingWorks

- Software File Name: Geometric-NestingWorks-2023-SP4-for-SolidWorks.rar

- Software Version: 2023 SP4

- File Size: 180 MB

- Developer: Geometric

System Requirements for Geometric NestingWorks 2020 SP1

- Operating System: Windows 10/8/7

- Free Hard Disk Space: 2 GB of minimum free HDD

- Installed Memory: 4 GB of minimum RAM

- Processor: Intel Multi-Core Processor or higher

Download Geometric-NestingWorks Latest Version Free

Click on the below link to download the latest offline setup of Geometric-NestingWorks-2023-SP4-for-SolidWorks for SolidWorks 2020 SP1.

File Password: 123