Download Process Engineering ToolS (PETS) v5 full version program free setup for Windows. Process Engineering ToolS (PETS®) software is used to model, size and analyze equipment and piping systems. PETS® software is trusted worldwide in the Energy, Chemical, Refinery and many other industries.

Process Engineering ToolS (PETS) Overview

Process engineering tools are essential instruments in the field of chemical and industrial engineering, enabling professionals to design, optimize, and control complex processes effectively. These tools are indispensable for a variety of industries, including petrochemical, pharmaceutical, food production, and manufacturing. Process engineers rely heavily on simulation software like Aspen Plus, CHEMCAD, and HYSYS. These tools allow engineers to model and analyze chemical and physical processes, helping them predict how changes will affect system behavior. It’s invaluable for process design, troubleshooting, and optimization. PFDs are visual representations of a process’s key components and their interactions. Tools like Microsoft Visio or specialized process diagram software help engineers create and document these diagrams, which are crucial for understanding and communicating complex processes. In industries where precise control of processes is critical, software like MATLAB and Simulink or distributed control systems (DCS) are used. These tools enable engineers to develop and implement control strategies, ensuring processes operate within desired parameters. Databases like Knovel or ChemSpider provide access to extensive libraries of chemical data, properties, and safety information. Engineers use these resources for material selection, process design, and hazard assessment. You may also like ChrisPC Win Experience Index 7.22.06

SPC software such as Minitab or JMP helps engineers monitor and control processes by analyzing data for variations and trends. It’s vital for maintaining product quality and consistency. Tools like AutoCAD Plant 3D or SolidWorks Process Piping are used for detailed process design, including equipment layout, piping, and instrumentation diagrams (P&ID). They ensure that the physical implementation of a process aligns with the design specifications. Optimization tools like GAMS or MATLAB’s Optimization Toolbox help engineers find the best operating conditions for processes, maximizing efficiency, and minimizing costs. This is crucial for competitiveness in many industries. Ensuring safety is paramount in process engineering. Software like PHAWorks or ALOHA assists in conducting hazard assessments, risk analyses, and emergency response planning. With an increasing focus on sustainability, energy management software like EnergyPlus or RETScreen is used to optimize energy usage in industrial processes, reducing costs and environmental impact. Historian software, such as OSIsoft PI or Honeywell Uniformance, collects and archives real-time process data. This information is invaluable for process analysis, troubleshooting, and improving overall efficiency. In industries like pharmaceuticals and specialty chemicals, batch processing software like DeltaV Batch or Werum PAS-X helps manage complex batch processes with multiple steps and variables.

Tools like COMSOL Multiphysics or ANSYS Fluent specialize in modeling and simulating specific aspects of processes, such as fluid flow, heat transfer, or chemical reactions. Process engineering tools not only streamline the design and operation of industrial processes but also contribute significantly to safety, efficiency, and sustainability. These tools empower engineers to make informed decisions, optimize operations, and ensure that products are manufactured with high quality and minimal environmental impact.

Features

- Process Simulation: Simulate and model complex processes to understand their behavior under different conditions, aiding in process design and optimization.

- Material Balance Calculations: Perform mass and energy balance calculations to ensure the conservation of materials and energy within a process.

- Chemical Reaction Modeling: Model chemical reactions within processes to study kinetics, yields, and product compositions.

- Thermodynamic Analysis: Use thermodynamic models to predict phase behavior, equilibrium constants, and properties of substances in the process.

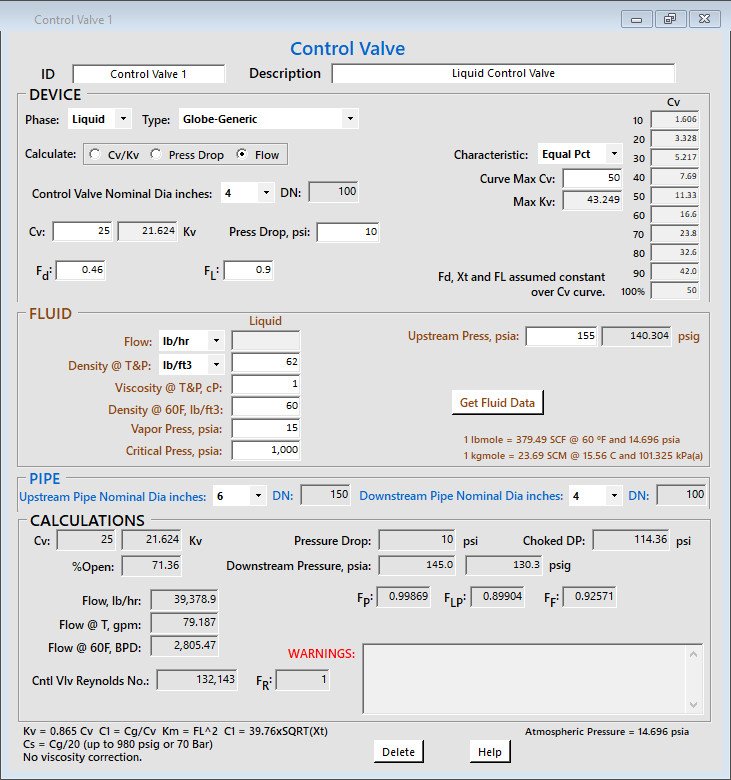

- Equipment Sizing: Size and select equipment such as reactors, pumps, and heat exchangers based on process requirements.

- Heat Exchanger Design: Design and analyze heat exchangers to optimize heat transfer and temperature control within the process.

- Pressure Drop Calculations: Calculate pressure drops in pipelines and equipment to ensure proper fluid flow and system efficiency.

- Piping and Instrumentation Diagram (P&ID) Creation: Generate detailed P&IDs that represent the process flow, equipment, and instrumentation.

- Process Control System Design: Design control systems, including the selection and configuration of control valves, sensors, and control strategies.

- Batch Processing Support: Support for designing and managing batch processes with multiple steps and recipes.

- Equipment Layout and 3D Modeling: Create equipment layouts and 3D models for accurate spatial representation of the process.

- Process Optimization: Employ optimization algorithms to find the best operating conditions for maximizing efficiency and minimizing costs.

- Safety Analysis: Perform hazard and risk assessments, including HAZOP studies, to ensure process safety.

- Environmental Impact Assessment: Evaluate the environmental impact of the process, including emissions and waste generation.

- Reliability Analysis: Assess equipment reliability and perform reliability-centered maintenance (RCM) analysis.

- Energy Efficiency Analysis: Analyze energy consumption and identify opportunities for energy conservation and efficiency improvements.

- Process Data Historian: Collect and archive real-time process data for analysis, troubleshooting, and historical reference.

- Process Monitoring and Alarm Systems: Set up monitoring systems to detect deviations from normal operating conditions and trigger alarms.

- Real-time Control: Implement real-time control strategies to maintain process variables within desired ranges.

- Data Visualization: Visualize process data through charts, graphs, and dashboards for better understanding and decision-making.

- Batch Tracking and Reporting: Track and report on batch processes, including recipe management and compliance tracking.

- Integration with PLC/DCS Systems: Integrate with programmable logic controllers (PLCs) and distributed control systems (DCS) for seamless process control.

- Process Historian Integration: Integrate with process historians to access historical data for analysis and reporting.

- Multi-phase Flow Analysis: Analyze multiphase flow systems, including gas-liquid and solid-liquid systems.

- Fluid Property Databases: Access extensive databases of fluid properties and chemical data for accurate modeling.

- Process Documentation: Generate documentation such as process flow diagrams, equipment datasheets, and standard operating procedures (SOPs).

- Collaboration Tools: Facilitate collaboration among team members by enabling data sharing and project management.

- Scenario Analysis: Analyze and compare different process scenarios to make informed decisions.

- Customization and Extensibility: Customize the tool to meet specific industry or company requirements and extend functionality through plugins or scripting.

- Multi-user Support: Allow multiple users to collaborate on projects simultaneously.

- Security and Access Control: Implement security measures to protect sensitive process data and control access.

- Cost Estimation: Estimate capital and operational costs associated with the process.

- Material Selection and Property Databases: Select appropriate materials for equipment and piping based on chemical compatibility and mechanical properties.

- Process Troubleshooting Tools: Provide diagnostic tools to identify and resolve process issues.

- Regulatory Compliance: Ensure compliance with industry and environmental regulations.

- Process Safety Management: Manage all aspects of process safety, including process safety information, process hazard analysis (PHA), and incident investigation.

- Instrumentation Database: Maintain a database of instrumentation and control devices used in the process.

- Training and Simulation: Use process simulation for operator training and virtual commissioning.

- Documentation Version Control: Implement version control for process documentation to track changes and revisions.

- Reporting and Analytics: Generate comprehensive reports and perform advanced analytics to drive continuous improvement.

Technical Details

- Software Name: Process Engineering ToolS (PETS) for Windows

- Software File Name: Process-Engineering-ToolS(PETS)-v5.02.rar

- Software Version: v5.02

- File Size: 27.5 MB

- Developers: processengineeringtools

- File Password: 123

- Language: Multilingual

- Working Mode: Offline (You donÆt need an internet connection to use it after installing)

System Requirements

- Operating System: Win 7, 8, 10, 11

- Free Hard Disk Space:

- Installed Memory: 1 GB

- Processor: Intel Dual Core processor or later

- Minimum Screen Resolution: 800 x 600

What is the latest version of Process Engineering ToolS (PETS)?

The developers consistently update the project. You can view the most recent software update on their official website.

Is it worth it to install and use Software Process Engineering ToolS (PETS)?

Whether an app is worth using or not depends on several factors, such as its functionality, features, ease of use, reliability, and value for money.

To determine if an app is worth using, you should consider the following:

- Functionality and features: Does the app provide the features and functionality you need? Does it offer any additional features that you would find useful?

- Ease of use: Is the app user-friendly and easy to navigate? Can you easily find the features you need without getting lost in the interface?

- Reliability and performance: Does the app work reliably and consistently? Does it crash or freeze frequently? Does it run smoothly and efficiently?

- Reviews and ratings: Check out reviews and ratings from other users to see what their experiences have been like with the app.

Based on these factors, you can decide if an app is worth using or not. If the app meets your needs, is user-friendly, works reliably, and offers good value for money and time, then it may be worth using.

Is Process Engineering ToolS (PETS) Safe?

Process Engineering ToolS (PETS) is widely used on Windows operating systems. In terms of safety, it is generally considered to be a safe and reliable software program. However, it’s important to download it from a reputable source, such as the official website or a trusted download site, to ensure that you are getting a genuine version of the software. There have been instances where attackers have used fake or modified versions of software to distribute malware, so it’s essential to be vigilant and cautious when downloading and installing the software. Overall, this software can be considered a safe and useful tool as long as it is used responsibly and obtained from a reputable source.

How to install software from the WinRAR file?

To install an application that is in a WinRAR archive, follow these steps:

- Extract the contents of the WinRAR archive to a folder on your computer. To do this, right-click on the archive and select ”Extract Here” or ”Extract to [folder name]”.”

- Once the contents have been extracted, navigate to the folder where the files were extracted.

- Look for an executable file with a .exeextension. This file is typically the installer for the application.

- Double-click on the executable file to start the installation process. Follow the prompts to complete the installation.

- After the installation is complete, you can launch the application from the Start menu or by double-clicking on the desktop shortcut, if one was created during the installation.

If you encounter any issues during the installation process, such as missing files or compatibility issues, refer to the documentation or support resources for the application for assistance.

Can x86 run on x64?

Yes, x86 programs can run on an x64 system. Most modern x64 systems come with a feature called Windows-on-Windows 64-bit (WoW64), which allows 32-bit (x86) applications to run on 64-bit (x64) versions of Windows.

When you run an x86 program on an x64 system, WoW64 translates the program’s instructions into the appropriate format for the x64 system. This allows the x86 program to run without any issues on the x64 system.

However, it’s important to note that running x86 programs on an x64 system may not be as efficient as running native x64 programs. This is because WoW64 needs to do additional work to translate the program’s instructions, which can result in slower performance. Additionally, some x86 programs may not work properly on an x64 system due to compatibility issues.

What is the verdict?

This app is well-designed and easy to use, with a range of useful features. It performs well and is compatible with most devices. However, may be some room for improvement in terms of security and privacy. Overall, it’s a good choice for those looking for a reliable and functional app.

Download Process Engineering ToolS (PETS) v5 Latest Version Free

Click on the button given below to download Process Engineering ToolS (PETS) free setup. It is a complete offline setup for Windows and has excellent compatibility with x86 and x64 architectures.