Download AutoForm TubeXpert R11 full version program free setup for Windows. AutoForm TubeXpert is an easy-to-use and highly intuitive software solution for rapid tool design and simulation of tube bending, forming, and hydroforming processes. The software enables you to meet the increasing demands regarding part complexity, part quality and advanced materials, such as advanced high-strength steels and aluminum, as well as the increasing complexity and variety of forming processes.

AutoForm TubeXpert R11 Overview

AutoForm TubeXpert stands as a cutting-edge software solution designed to revolutionize the tube and pipe bending process in the field of manufacturing and engineering. Developed by AutoForm Engineering, a leader in the field of simulation software for sheet metal forming, TubeXpert extends the company’s expertise to the domain of tubular components. The primary objective of this software is to provide a robust and intuitive platform for engineers and manufacturers to design, analyze, and optimize tube bending processes.

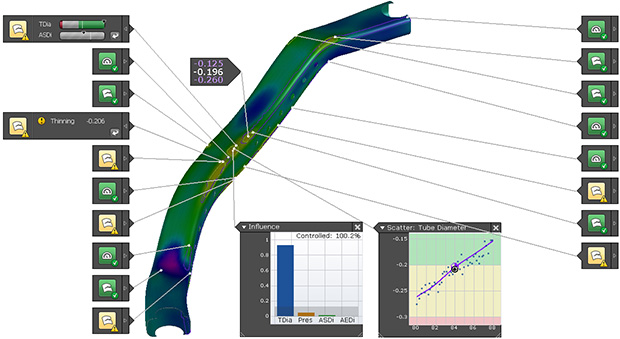

One of the defining features of AutoForm TubeXpert is its advanced simulation capabilities. The software allows users to simulate the entire tube bending process, predicting and analyzing potential issues such as material deformation, wrinkling, or springback. This simulation-driven approach empowers engineers to identify and rectify potential challenges in the design phase, leading to improved efficiency and cost-effectiveness in the manufacturing process.

The software’s user-friendly interface enhances the overall user experience, allowing for easy navigation and interaction with the modeling tools. TubeXpert supports various tube and pipe geometries, accommodating a wide range of applications across industries. Its versatility extends to handling different materials, wall thicknesses, and bending radii, making it a versatile tool for diverse manufacturing requirements.

Another standout feature is collision detection, which plays a crucial role in ensuring the feasibility of tube bending processes. By identifying potential collisions between the tube and the bending machine, TubeXpert aids in preventing errors and minimizing material wastage during production.

In addition to its simulation prowess, AutoForm TubeXpert offers optimization tools to enhance the efficiency and accuracy of the tube bending process. Engineers can iteratively refine their designs based on simulation results, achieving optimal results in terms of quality and resource utilization.

The software’s commitment to providing a comprehensive solution is further exemplified through its integration capabilities. TubeXpert seamlessly integrates with other AutoForm products, creating a cohesive ecosystem for manufacturers involved in both sheet metal forming and tube bending.

In summary, AutoForm TubeXpert emerges as a powerful tool for the tube and pipe bending industry, offering advanced simulation capabilities, a user-friendly interface, collision detection, optimization tools, and seamless integration within the AutoForm suite. Its application extends to a variety of industries, providing engineers and manufacturers with a sophisticated solution for enhancing the efficiency and accuracy of tube bending processes.

Features

- Tube and Pipe Bending Simulation: Advanced simulation capabilities for the entire tube bending process.

- Simulation-Driven Design: Predicts and analyzes potential issues such as material deformation, wrinkling, and springback during the design phase.

- Intuitive Platform: Provides an intuitive and user-friendly platform for designing, analyzing, and optimizing tube bending processes.

- Versatile Geometry Support: Supports various tube and pipe geometries, accommodating a wide range of applications.

- Material Flexibility: Handles different materials, wall thicknesses, and bending radii for diverse manufacturing requirements.

- User-Friendly Interface: Ensures easy navigation and interaction with modeling tools for an enhanced user experience.

- Collision Detection: Identifies potential collisions between the tube and bending machine to prevent errors and minimize material wastage.

- Optimization Tools: Offers tools for iterative design refinement based on simulation results, optimizing tube bending processes.

- Feasibility Analysis: Assesses the feasibility of tube bending designs, improving the overall efficiency of the manufacturing process.

- Quality Assurance: Enhances quality assurance by identifying and rectifying potential challenges in the design phase.

- Resource Utilization Optimization: Aids in optimizing resource utilization through iterative design improvements.

- Material Deformation Analysis: Analyzes material deformation during the bending process to ensure accurate predictions.

- Wrinkling and Springback Analysis: Predicts and addresses issues such as wrinkling and springback, enhancing manufacturing precision.

- Versatile Application: Applicable to various industries with diverse tube bending requirements.

- Support for Different Bending Machines: Compatible with different types of tube bending machines for increased flexibility.

- Process Efficiency: Improves overall process efficiency by addressing design challenges before production.

- Iterative Design Refinement: Allows engineers to iteratively refine designs based on simulation results for optimal outcomes.

- Seamless Integration: Integrates seamlessly with other AutoForm products for a cohesive manufacturing ecosystem.

- Comprehensive Solution: Provides a comprehensive solution for tube and pipe bending challenges.

- Predictive Analysis: Utilizes predictive analysis to foresee potential issues and improve the design process.

- Error Prevention: Helps prevent errors and reduce the likelihood of material wastage during tube bending.

- Production Cost Reduction: Contributes to the reduction of production costs through efficient design and optimization.

- Tooling Optimization: Optimizes tooling processes for increased efficiency and reduced production time.

- Process Validation: Validates tube bending processes through accurate and reliable simulations.

- Iterative Workflow: Facilitates an iterative workflow for continuous improvement in design and production.

- Collaborative Design Environment: Supports collaboration among design and manufacturing teams for enhanced communication.

- Realistic Simulation Results: Provides realistic simulation results for better-informed decision-making.

- Quality Control Measures: Incorporates quality control measures to ensure high standards in tube bending.

- Efficient Tube Design: Enhances the efficiency of tube design through simulation-driven insights.

- Resource Management: Efficiently manages resources by identifying and addressing design challenges early in the process.

Technical Details

- Software Name: AutoForm TubeXpert R11 for Windows

- Software File Name: AutoForm-TubeXpert-R11.rar

- Software Version: R11

- File Size: 460 MB

- Developers: autoform

- File Password: 123

- Language: Multilingual

- Working Mode: Offline (You donÆt need an internet connection to use it after installing)

System Requirements

- Operating System: Win 7, 8, 10, 11

- Free Hard Disk Space:

- Installed Memory: 1 GB

- Processor: Intel Dual Core processor or later

- Minimum Screen Resolution: 800 x 600

What is the latest version of AutoForm TubeXpert R11?

The developers consistently update the project. You can view the most recent software update on their official website.

Is it worth it to install and use Software AutoForm TubeXpert R11?

Whether an app is worth using or not depends on several factors, such as its functionality, features, ease of use, reliability, and value for money.

To determine if an app is worth using, you should consider the following:

- Functionality and features: Does the app provide the features and functionality you need? Does it offer any additional features that you would find useful?

- Ease of use: Is the app user-friendly and easy to navigate? Can you easily find the features you need without getting lost in the interface?

- Reliability and performance: Does the app work reliably and consistently? Does it crash or freeze frequently? Does it run smoothly and efficiently?

- Reviews and ratings: Check out reviews and ratings from other users to see what their experiences have been like with the app.

Based on these factors, you can decide if an app is worth using or not. If the app meets your needs, is user-friendly, works reliably, and offers good value for money and time, then it may be worth using.

Is AutoForm TubeXpert R11 Safe?

AutoForm TubeXpert R11 is widely used on Windows operating systems. In terms of safety, it is generally considered to be a safe and reliable software program. However, it’s important to download it from a reputable source, such as the official website or a trusted download site, to ensure that you are getting a genuine version of the software. There have been instances where attackers have used fake or modified versions of software to distribute malware, so it’s essential to be vigilant and cautious when downloading and installing the software. Overall, this software can be considered a safe and useful tool as long as it is used responsibly and obtained from a reputable source.

How to install software from the WinRAR file?

To install an application that is in a WinRAR archive, follow these steps:

- Extract the contents of the WinRAR archive to a folder on your computer. To do this, right-click on the archive and select ”Extract Here” or ”Extract to [folder name]”.”

- Once the contents have been extracted, navigate to the folder where the files were extracted.

- Look for an executable file with a .exeextension. This file is typically the installer for the application.

- Double-click on the executable file to start the installation process. Follow the prompts to complete the installation.

- After the installation is complete, you can launch the application from the Start menu or by double-clicking on the desktop shortcut, if one was created during the installation.

If you encounter any issues during the installation process, such as missing files or compatibility issues, refer to the documentation or support resources for the application for assistance.

Can x86 run on x64?

Yes, x86 programs can run on an x64 system. Most modern x64 systems come with a feature called Windows-on-Windows 64-bit (WoW64), which allows 32-bit (x86) applications to run on 64-bit (x64) versions of Windows.

When you run an x86 program on an x64 system, WoW64 translates the program’s instructions into the appropriate format for the x64 system. This allows the x86 program to run without any issues on the x64 system.

However, it’s important to note that running x86 programs on an x64 system may not be as efficient as running native x64 programs. This is because WoW64 needs to do additional work to translate the program’s instructions, which can result in slower performance. Additionally, some x86 programs may not work properly on an x64 system due to compatibility issues.

What is the verdict?

This app is well-designed and easy to use, with a range of useful features. It performs well and is compatible with most devices. However, may be some room for improvement in terms of security and privacy. Overall, it’s a good choice for those looking for a reliable and functional app.

Download AutoForm TubeXpert R11 Latest Version Free

Click on the button given below to download AutoForm TubeXpert R11 free setup. It is a complete offline setup for Windows and has excellent compatibility with x86 and x64 architectures.